|

Measuring moisture (H20) in active and corrosive gases is a very difficult problem. There is the fundamental problem of differentiating between moisture in the background purge of the instrument and moisture in the gas to be measured. Another design consideration is the problem of the instrument being able to hold up to the chemical activity of the gases themselves.

The overall system has been designed to handle a number of problems that have been present in previous FTIR systems measuring moisture in corrosive gases. This the meaning of ‘Solutions by Design”.

Special Design Considerations for the Moisture Analyzer

- Pathlength for gas cell is 6.1 meters

- Pathlength of the purged IR beam in enclosure is less that 10% of pathlength in gas cell

- Hermetically sealed (vacuum) enclosure for excellent purge and dry down (purge cycling possible for rapid dry down)

- High energy throughput gas cell

- KBr windows for high energy throughput

- TE-cooled MCT detector provides high (D*) performance without requirement of liquid nitrogen cooling

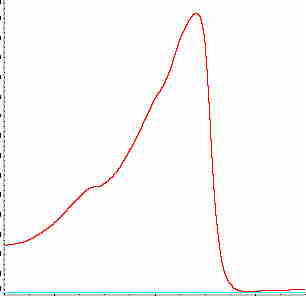

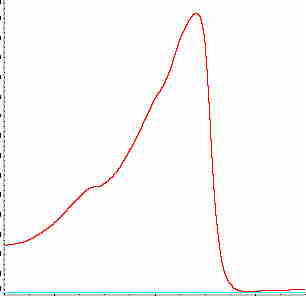

- TE-cooled MCT detector acts as a band pass IR filter because it has a frequency cut-off around 2400 cm-1 allowing ADC to be filled with more of signal to be measured

- Broadband liquid nitrogen cooled or Sterling cycle cooled MCT detectors are available as options.

- "Artificial Reference" software eliminates requirement for reference gas or evacuation of the gas cell to obtain a single beam background spectrum

- FTIR interferometer with KBr beamsplitter for highest signal to noise performance or optional ZnSe beamsplitter for moisture resistance in non purged environments

- FTIR interferometer has dynamic alignment, which provides short term and long term stability and automatic interferometer alignment without operator involvement

- Gas cell has 304 stainless steel conflat flanges, metal - metal seals (copper or nickel) and 304 stainless steel cell body construction for sample wetted surfaces, and highly protective magnesium fluoride over highly reflective gold coating over nickel coated solid stainless steel mirror substrate for long term chemical resistance

- Mirror surfaces are vertical to minimize dust or corrosive particles forming on their surface maximizing time between cleaning

|

5,000 cm-1 2,400 cm-1

Single Beam Spectrum

Thermoelectrically cooled MCT Detector

LN2 and TE-cooled Detectors available on request

(low frequency cut-off ~2400 cm-1)

|